Our Commercial Bakery Slicers

Any Way You Want to Slice it...

A Ryan is Always Best

At Ryan Technology, we specialize in delivering top-tier slicing equipment engineered for performance, durability, and consistency. Our industry-leading commercial bakery slicer and commercial bun slicer systems are designed to meet the rigorous demands of modern bakeries, sandwich production facilities, and food processing plants across the globe.

Increase Production Efficiency Without Sacrificing Quality

Time is critical in high-output environments. That’s why Ryan Technology’s slicers are built to streamline your slicing operations while preserving the texture, structure, and presentation of every baked product. Whether you’re slicing rolls, buns, bagels or croissant, our commercial slicers handle the job with unmatched speed and precision — without compromising quality.

Achieve Uniform Results With Every Slice

Our commercial bakery slicer solutions are engineered with high-torque motors, precision blades, and adjustable slicing guides to ensure uniform thickness, perfect alignment, and minimal product waste. Consistency is key in large-scale baking, and our slicers help you deliver the exact same cut, every single time.

Simplify Operations With User-Friendly Design

At Ryan Technology, we understand that ease of use matters. That’s why our slicers are built with intuitive controls, easy blade access, and easy-to-clean components. Your team can operate and maintain the machines efficiently, reducing downtime and increasing productivity. Whether you need a fully automatic or semi-automatic solution, our commercial bakery slicers are designed to simplify every step of your workflow.

Maximize Hygiene and Food Safety Standards

Sanitation is critical in commercial baking environments. Ryan Technology slicers are crafted with food-grade stainless steel and open-frame construction to meet the highest hygiene standards. Cleaning and maintenance are quick and straightforward, ensuring compliance with food safety regulations while minimizing labor time.

Customize Your Solution for Specific Needs

No two bakeries are the same. That’s why we offer configurable options for both our commercial bun slicer and rotary bakery slicer lines. Whether you require in-line integration with conveyors, or special handling for delicate buns or artisan breads, our equipment can be tailored to fit your unique production line and baked goods.

Trust Over 30 Years of Industry Experience

With more than three decades of experience in bakery slicing technology, Ryan Technology is a trusted name in the industry. Our machines are proudly engineered and assembled in the USA, with a commitment to quality craftsmanship and responsive customer support. From installation and training to ongoing service, our team is here to support your long-term success.

Get Started With a Custom Quote Today

Whether you're upgrading your current equipment or launching a new production line, Ryan Technology offers slicing solutions that help you scale without sacrificing quality. Contact us today to learn more about our commercial bakery slicer and commercial bun slicer systems — and discover how our technology can take your operation to the next level.

Models 793, 1193, 1097, 901, 904

For volumes under 10,000 pieces per hour and when baking on pans and racks, Ryan Technology offers several rotary table models.

All of the below models include the following features and options:

- USDA approved powder-coated tubular steel frame. (Stainless frame optional)

- Nickel plated steel blade housings, conveyors, and guards.

- 1 Hp motors with brakes on blade motors.

- Magnetic interlock switches on blade covers.

- Adjustability for cut height, depth, and product height and width.

- Single- or dual-blade versions.

- Optional Ryton coated blades.

- Optional turn table/conveyor variable speed drive.

- Right-hand or left-hand configuration.

- Available as 208 or 240 volt 3-phase 60Hz. (50Hz power also available)

Model 793 Rotary Table Utility Slicer

Designed with simplicity and rugged durability in mind, the Model 793 Rotary Table Utility Slicer is a versatile machine for small to mid-sized bakeries. It has a 3-foot diameter turn table and a 5-1/2 inch wide conveyor. The 793 is available in two versions: a single-blade version (793A) for side-hinge slicing, or a dual-blade version (793B) with two opposing 12 inch blades for butterfly cutting. It is effective and economical at cutting product at up to 8,000 pieces per hour. You can find the Spec Sheet here.

Click to See Larger Photo

Model 1097 Rotary Table Utility Slicer

This rotary table slicer is a larger version of the 793 machine, with a 4 foot diameter table, an 8 inch wide conveyor, and 14 inch blades—capable of slicing wider products. You can find the Spec Sheet here.

Click to See Larger Photo

Model 1193 Utility Slicer

For long products that do not feed well in a rotary table, such as French loaves and baguettes, there is the Model 1193 Utility Slicer. It is much like the 793, but instead of the rotary table there is a flat stainless table with a conveyor running along one side. The 1193 can also be placed in-line with another in-feeding conveyor to further automate your slicing. A wide conveyor for clustered product is an available option. You can find the Spec Sheet here.

Click to See Larger Photo

Model 901 Croissant Slicer

The Model 901 Croissant Slicer is very similar to the 793. Designed around large croissants, the 901 has a 7 inch wide conveyor and a space between the turn table and the blades to allow more time for the product to settle flat before being sliced. This slicer also still has all the versatility of the 793. You can find the Spec Sheet here.

Click to See Larger Photo

Model 904 Sub Roll Slicer

The Model 904 Sub Roll Slicer is a rotary table unit with an optional in-feed conveyor and a space before the blades where the operator can, if necessary, turn product right-side-up before it is sliced. See the video of this slicer on our Resources Page. You can find the Spec Sheet here.

Click to See Larger Photo

Automated Lines

Slice Your Costs at High Speed

All 890 series slicers were designed with continuous operation in mind. Our unique, blade change on-the-fly design allows for no shut-down blade cleaning. When it is time to clean blades, a turn of a switch on the control panel will bring in the reserve set of blades and your line can continue running while the dirty blades are taken out and cleaned. Standard features on all 890 series slicers include:

- Production speeds up to 400 pieces per minute.

- Magnetic interlock safety switches on blade access doors.

- 1 Hp blade motors with brakes.

- A neutral setting to allow product to flow through without being sliced.

- Air operated blade change system.

- Stainless frame, blade housing, conveyors, and guards.

- Optional Ryton coated blades.

- Adjustability for cut height, depth, and product height and width.

- A 6 inch wide conveyor is standard. (Other widths optional)

We can also offer help getting your product into a single-line to feed into the slicers

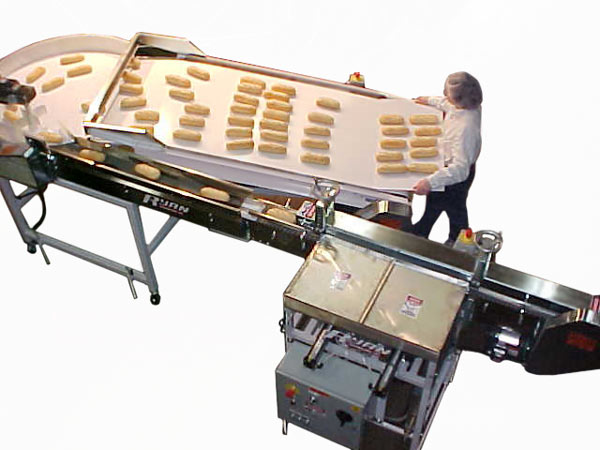

Model 797 Table In-Feed Unit

The Model 797 Rotary Table aligns product into a single lane and can be used in conjunction with a Model 890 series slicer or on its own.

Click to See Larger Photo

Model 892 Center-Hinge Butterfly Slicer

The Model 892 Center-Hinge Butterfly Slicer features four 12 inch circular blades for butterfly slicing (center-hinge). Two opposing blades cut while the other two are in reserve. You can find the Spec Sheet here.

Click to See Larger Photo

Model 894 In-Line Side-Hinge Slicer

The Model 894 In-Line Side-Hinge Slicer is a side-hinge cutting machine with two 14 inch blades. You can find the Spec Sheet here.

Click to See Larger Photo

Model 894 In-Line Side-Hinge Slicer shown in lower right corner.

Model 797 Rotary Table Infeed also displayed.

Model 8903 Dual Use Slicer

The newest unit in this series, the Model 8903 Dual Use Slicer, combines the features of both the 892 and the 894 into one machine. It has four 12 inch blades for butterfly cutting and two 14 inch blades for side-hinge cutting. You can find the Spec Sheet here.

Click to See Larger Photo